Technology is currently evolving quickly and continuously. Another product of technology is 3D printing. But first, you might be curious about is 3D printing hard?

3D printing is quite hard, especially for beginners. It requires creativity, math, and computer-aided design (CAD) skills to master. However, 3D printing becomes simpler once you have the required hardware and software, modeling expertise, and a comprehension of how this technology works.

We’ll go over the technology required for 3D printing in this article along with why it can be complicated. For details on these, as well as the advantages and disadvantages of this technology, continue reading.

Table of Contents

What is 3D Printing?

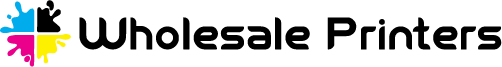

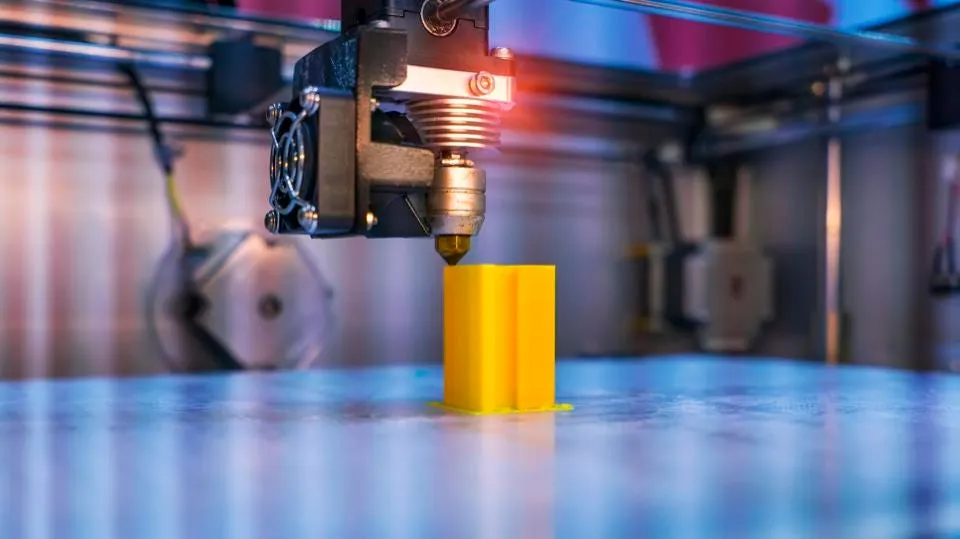

3D printing is the process of creating physical objects from digital models. A “file,” usually in The product is sent to a 3D printer in STL format, which will assemble it layer by layer until it is fully printed.

3D printing is the successor to Since Chuck Hull developed stereolithography in 1984, CNC machining has been a thing. Since then, 3D printers have been used for everything, from art-making to scientific research, but they are still gaining mainstream popularity.

Is 3D Printing Hard to Learn?

3D printing is still in its infancy, and as a result, not very user friendly. For beginners, using a printer can be overwhelming because they are delicate and difficult to maintain. Those who want to make their own designs must also invest time in learning specialized and frequently difficult software.

3D printing is an exciting technology, and those willing to weather its challenges will likely find their efforts fruitful. Before jumping in headfirst, it is important to know what to expect and prepare yourself for confronting obstacles along the way.

Related Post: How Long Does It Take to 3D Print?

Why 3D Printing is Hard

3D printing is complex because it attempts to combine the processes of creating and assembling a physical object from start to finish. An object must first be designed using CAD software before it can be 3D printed. It’s possible that this process calls for engineering, math, and creativity.

Designing requires time even for simpler objects because there are no industry standards when using CAD software. Every company has its ways of interacting with these programs, and designs vary from one program to another.

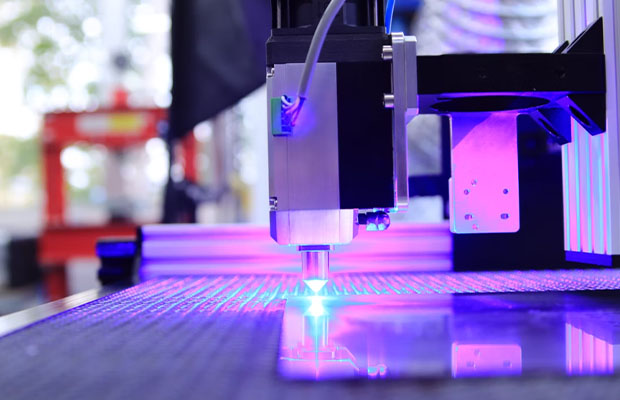

A lot more goes into 3D printing than just clicking “Print” on your computer screen. Before designing a product, different materials’ unique properties must be taken into account.

The thickness of a material, for instance, affects how its design will be printed and could also have an impact on how well a product functions. A thin material may snap or break easily when handled.

The printing process is no longer as easy as pressing a button once you have designed an object and chosen the appropriate material. The build area, or starting and stopping point for printing, must be selected when configuring the printer.

There is also the build volume, or the maximum size of an object that can be printed in a single session.

Also Read: Is 3D Printing An Expensive Hobby?

The Benefits of 3D Printing

3D printers have many practical applications, such as testing new products and making repairs on machinery.

The ability to design personalized prosthetics and better training models for surgeons is a benefit for medical professionals as well.

Besides saving lives, they also save money by allowing designers to test things like shoe soles and aerodynamic helmets before making a large investment.

The Limitations of 3D Printing

The hype around 3D printing has made it seem like a miracle product that will revolutionize manufacturing and change our lives as we know it. While there is no doubt that 3D printing will eventually be used in countless ways, there are certain limitations to consider before you put one on your wishlist:

- It takes longer than you would anticipate. While a CAD file may look simple on the screen, it takes time to “slice” into thin layers for printing. Because of this, printing objects that take 30 minutes on FDM printers can occasionally take hours or even days when using more sophisticated techniques like DLP printing.

- Materials cost more than they appear to. Plastics come in a wide variety with various uses and characteristics that can be purchased. These plastics can be quite pricey if you don’t have a top-tier brand printer. For more information, read on How To Reduce Cost Of 3D Printing.

- There is a restricted print run. Although some FDM printers can produce objects the size of a basketball, most are much smaller for practical reasons. It’s not always possible to scan an object and then print it perfectly scaled up.

- Income is lost during downtime. Suppose your 3D printer fails during working hours. In that case, it may mean you lose money during a scheduled break or an important presentation.

- Regarding 3D printing, there are a lot of unanswered questions. Due to the constant development of new materials and technologies, your printer’s maintenance and repairs may incur unforeseen costs. It’s not always simple to identify the problem when one of these printers breaks down because they are so complicated.

What is Needed for 3D Printing?

To begin 3D printing, you obviously need to purchase a 3D printer. A computer is a requirement as well. Any computer with a respectable internet connection will suffice if all you intend to do is download pre-made files and print them.

3D design will require much more in terms of computing performance. Minimum specs for such a computer include 8 GB of memory and a CPU with a high clock speed, while the optimal experience requires 16 GB of memory and a dedicated graphics card alongside the CPU.

Similar to how a regular printer requires ink, you will need a material to print with once your 3D printer is set up. The ability to print with a variety of materials, including ABS, carbon fiber, and nylon, is one of the most appealing aspects of 3D printing. 3D printers take these materials in the form of filament. Research is required before deciding which material is best for your project because each one is suited to a particular purpose.

Knowing where to find 3D design files is helpful whether or not you intend to create your own designs. Some of the most well-known sites include:

- Thingiverse

- Cults3D

- Pinshape

Final Thoughts on is 3D Printing Hard

For many, 3D printing is a challenging task to take on successfully from beginning to end. To finish a project, an artist’s creativity needs to be combined with math and engineering expertise.

You’ll occasionally make mistakes, but they’re all teaching moments. Prints should come out fairly smoothly most of the time with a few setting adjustments.

3D printing is a fantastic technology to experiment with if you plan ahead and are aware of your limitations.

Read More: How Much Power Does A 3D Printer Use?

FAQs

Is 3D Printing Expensive?

3D printing can cost anywhere from $3 up to thousands of dollars. Without a 3D model, it can be challenging to determine the exact cost of a 3D print.

Is 3D Printing Profitable?

Yes, 3D printing can be profitable because it is a quickly growing industry, with most businesses discovering opportunities for success.

Are 3D Printers Worth It?

Only if 3D printing is a hobby or passion you want to develop further or learn more about is it worthwhile to purchase a 3D printer.