Some manufacturing companies may encounter string when performing 3D printing. Stringing in 3D printing can be very frustrating, lines that form on objects are unsightly and leave a residue when removed. Therefore, it is important to avoid cross-threading as much as possible before printing. So, what exactly is causing the tandem in 3D printing?

Table of Contents

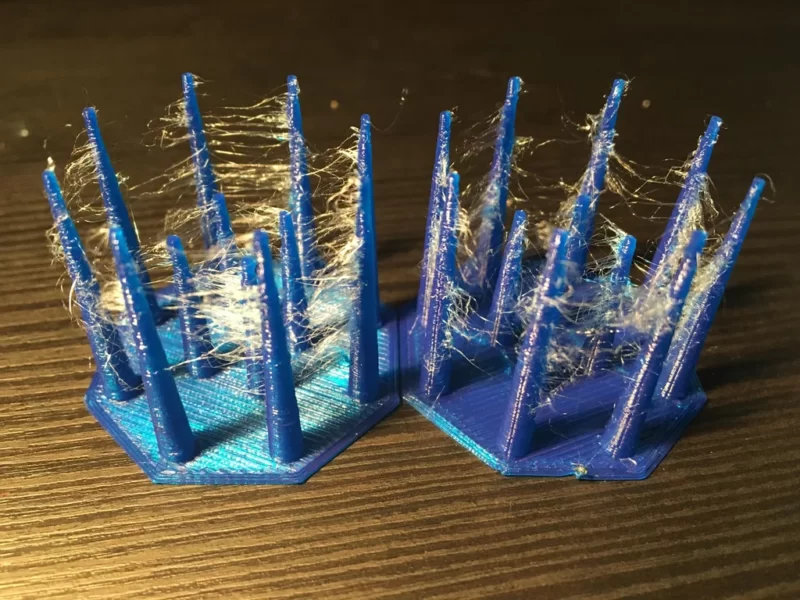

Overview of Stringing

Stringing, also known as dripping or oozing, is a 3D printing phenomenon in which excess and unwanted material remain on an object after printing. In other words, the finished product does not have the exact dimensions it should have. It contains extra material, usually on the sides and edges of the finished product.

This is called a “string” because the excess and unwanted material often resembles a string. It consists of long and narrow chains of material used to make prints. When the material hangs on the sides of the object, it looks like a string.

Common Causes of Stringing in 3D Printing

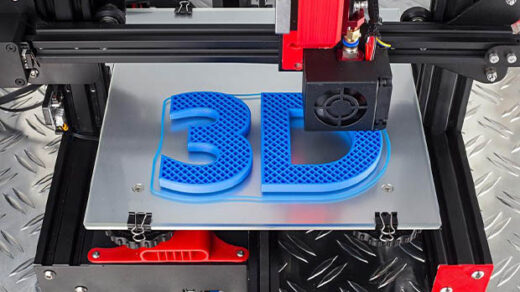

3D printing is an additive manufacturing process that creates three-dimensional objects from computer-aided design (CAD) models or other 3D digital data sources. Objects are created by continuously adding materials layer by layer until the desired shape is obtained. However, sometimes this process can go wrong and the result is not a single entity but a mess.

This phenomenon is called 3D printing streaking, and there may be several reasons for this:

- A common cause of stringing is over extrusion, which occurs when too much filament is extruded from the nozzle. This can be caused by a clogged nozzle or an incorrect squeeze setting.

- Another possible cause is airflow, which can cause the molten filament to cool and harden before reaching the forming plate.

- Finally, poor-quality filaments that break easily or ooze can also cause stringing.

Whatever the reason, the string can be frustrating for anyone who enjoys 3D printing. Fortunately, there are simple ways to reduce the risk of string, such as keeping the nozzle clean and using high-quality filament.

With a little trial and error, you should be able to achieve consistent, high-quality results.

Does Print Speed Affect Stringing?

If you’re a 3D printing hobbyist, you might be wondering if printing speed affects string. In short, the answer is yes – printing speed definitely affects the string. But why?

String occurs when the extruder moves around the build platform, leaving behind small filaments of plastic. This usually happens when plastic is not heated properly, causing it to become sticky. Printing speed can exacerbate this problem because it puts more pressure on the plastic, making it more likely to string together.

So if you notice a lot of cross-threading on your prints, one solution is to slow down the print speed. Of course, this also extends the overall print time, so it’s not always practical.

However, if you’re willing to sacrifice some time for better results, then lowering the print speed can go a long way towards reducing the stringing.

Does Wet Filament Cause String?

Any 3D printer user knows that string can be a frustrating problem. This is especially common in long, thin prints, such as vases or candlesticks.

But what causes the string, and what can be done to prevent it? Stranding occurs when molten plastic seeps out of the nozzle during printing.

There are many reasons for this to happen, but one of the most common is wet silk. When the fiber is wet, it does not flow as smoothly in the extruder. As a result, more plastic is squeezed out of the nozzle than usual, resulting in tandem.

The best way to prevent this from happening is to make sure the filament is always stored in a dry, airtight container.

With this simple step, you can keep the filament in good condition and avoid the frustration of string.

Solutions for Stringing in 3D Printing

There are several solutions to help avoid tandem in 3D printing.

1. Use an edge or a raft.

This will help prevent objects from moving around during printing and will also provide extra support which will help avoid cross-threading

2. Increase the shrinkage distance.

This will help reduce the amount of filament extruded, which in turn will help reduce string.

3. Use a smaller nozzle size.

This also helps reduce the number of filaments that are squeezed and therefore helps lower the string.

4. Improve the printer speed.

This may seem counterintuitive, but faster prints tend to have less stitching than slower prints.

5. Lower the ambient temperature.

Elevated temperatures can cause the filament to degrade, which can lead to string. So, if you notice a lot of stringing, try turning the temperature down!

By following these simple tips, you should be able to reduce or eliminate concatenation in your prints. So, go ahead and print with confidence! Your perfect fingerprint is waiting.

In Conclusion

The string is a 3D printing phenomenon that involves adding excess and unwanted material to the printed object. Material looks like a string, that’s how it receives an object of the same name. This can happen when the 3D printer is set to high heat or high speed. By adjusting the temperature and speed of their 3D printers, manufacturing companies can prevent this from happening.