Stereolithography, the technology behind most resin 3D printing, is often referred to as the “mother of all 3D printing technologies” and is considered one of the most widely used techniques for producing high-quality 3D prints. Resin 3D printers have been popular for a while now, mainly because of their ease of use and a significant drop in price. This has left many wondering what exactly a resin 3D printer is and how it works. Keep reading this article for more in-depth information on those awesome resin 3D printers.

Table of Contents

What is a Resin 3D Printer?

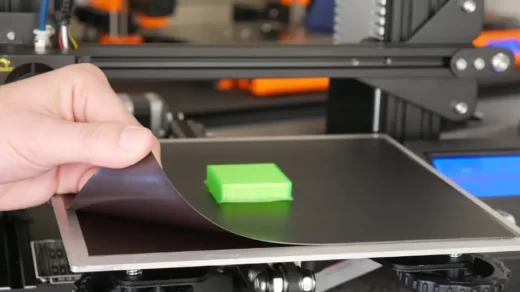

A resin 3D printer is a machine that holds a barrel of light-sensitive liquid resin and exposes it layer by layer to an ultraviolet LED beam to harden the resin into a plastic 3D model. Known as SLA or stereolithography, the technology can provide 3D printing with extremely fine detail at 0.01mm layer heights.

When choosing a 3D printer, you mainly have two options, the first is a filament 3D printer, commonly known as FDM or FFF 3D printer, and the second is a resin 3D printer, also known as SLA or MSLA 3D printer.

If you look at the resulting models printed with these two different techniques, you may notice a huge difference in quality. Resin 3D printers are capable of printing 3D models with ultra-smooth surfaces and fine detail.

FDM 3D printers may not be able to print such high-quality models due to positioning accuracy, nozzle size, and large layer height capabilities.

Read More:

The Pros and Cons of Resin Printers

Pros

- Resin printers provide more detailed and smoother models.

- Resin prints don’t require extensive finishing and look great.

- They are faster than FDM machines.

- Resin models are generally stronger and more resilient.

Cons

- Resin printing is generally more expensive.

- It’s messier and requires more maintenance.

- You need to prepare a safe environment to print and store resin.

- The average build volume for resin printers is smaller.

- Uncured resin is toxic and must be handled with care.

It is important that any potential resin printer owner be fully prepared for the realities, hazards, environmental concerns, and maintenance burdens of resin printing.

How Do Resin Printers Work

Resin 3D printers are one of the most popular printers on the market today. Learn how resin 3D printers work.

Resin 3D printers have grown in popularity in recent years. This is mainly due to its ease of use and cost-effectiveness. Unlike other 3D printers that use filament and powder materials, resin printers are relatively inexpensive in terms of initial, ongoing, and overall maintenance costs. They also made 3D prints with super smooth and finer details.

They are mainly suitable for creating small to medium objects in the home and office spaces. While resin 3D printers are quite popular, most people don’t understand how they work. As a result, they usually buy machines and end up frustrated when they use them. The following article explains how resin 3D printers work.

Types of Resin 3D Printing

Resin 3D printing is the technology in which liquid resin is stored in a container instead of being injected through a nozzle. The major terms or types of resin 3D printing include Stereolithography (SLA), Digital Light Processing, Liquid Crystal Display (LCD), or Masked Stereolithography (MSLA).

SLA

SLA stands for Stereolithography, and SLA resin 3D printers work with the help of a UV laser applied to the surface of a photopolymer container (mainly called a resin barrel).

Light is applied in a specific pattern to form the desired shape.

The SLA 3D printer includes various components such as a building platform, resin barrel, light source, elevator, and a pair of galvanometers.

The main purpose of the lift is to increase or decrease the height of the building platform in order to form layers during the printing process. The galvanometer is a pair of movable mirrors that are used to align the laser beam.

Since the resin tank contains uncured resin, it hardens in layers under the influence of UV light and begins to form a three-dimensional model. Resin 3D printers print layer by layer, repeating the process until a fully 3D printed model of the object is complete.

DLP

The digital light processing technology is almost similar to SLA, but instead of lasers, it uses a digital projection surface as the light source.

While using SLA technology to print only one dot at a time, DLP resin 3D printing works by printing one complete layer at a time. This is why DLP resin 3D printing is so much faster than SLA.

They are also considered very reliable as it is not a complex system with no moving parts.

A DMD (Digital Micromirror Device) is a device used to control the precise application position of the projection in a resin 3D printer.

DMDs consist of hundreds to millions of micromirrors that project light at different points and print layered patterns in a better way while integrating the entire layer.

The image of the layer is mainly composed of pixels, as the digital display is the starting point for any layer formed by the DLP 3D printer. In 3D printing, the dots exist in the form of prisms that can be seen from all three angles.

After printing one layer, raise the platform to a specific height in order to print the next layer of the model.

The main advantage of 3D printing with DLP resin is smoother and faster printing. One thing to note here is that the increase in the print area significantly reduces the processing quality.

MSLA/LCD

DLP and SLA can be distinguished from each other, but you may get confused when discovering the difference between DLP and MSLA or LCD (Liquid Crystal Display).

It is known that DLP 3D printing requires additional micromirror devices to transmit light from the projector, but such devices are not required when printing with LCD 3D printers.

The UV beam of light comes directly from the LEDs and shines through the LCD screen. Since this LCD screen is used as a mask, the LCD technology is also widely known as MSLA (Mask SLA).

Since the invention of this MSLA/LCD technology, resin 3D printing has become more popular and more accessible to ordinary people.

This is because individual or add-on components for LCD 3D printing are relatively inexpensive. Keep in mind that LCD 3D printers have a slightly shorter lifespan than DLP chipsets and generally require more maintenance.

Despite this drawback, LCD/MSLA 3D printing is popular due to its smoother surface and relatively fast printing speed. Pixel distortion is an important factor in resin 3D printing, much lower than DLP resin 3D printing.

The actual light from LCD screens is known to be detrimental to the organic compounds in it, which means you have to change them based on age and performance.

Who Should Buy a Resin Printer?

The main market for desktop resin printers is those who need to make small, detailed models. For example, if you want to create details for a tabletop game or intricate 3D jewelry, a resin printer might be a good choice. If you’re a 3D sculptor using software like Zbrush, only a resin printer can handle your detailed models well.

It is entirely possible to paint resin models, but a lengthy process needs to be followed to prepare the resin surface to accommodate the paint. If you don’t need the detail and quality of resin printing, then you’re better off going with an FDM 3D printer. You can also improve the surface quality of your FDM prints by using techniques such as sanding for smoother model surfaces.

How Much Are Resin 3D Printers?

Like the ElegoMars Pro, resin 3D printers start at around $250. Like the Anycubic Photon Mono X, you can get a good mid-range resin 3D printer for $350-800, and like the Formlabs 3, a top-of-the-line professional resin 3D printer can cost upwards of $3000. They are getting cheaper.

Resin 3D printers can be considered simple machines as they do not include many moving parts. This is why resin 3D printers can be purchased at relatively low prices. Most of its components are what we use in our daily life, such as LCD screens.

Conclusion

Resin printers use light-curing UV resin as the print medium. The resin is exposed to a UV light source, which cures the resin, causing it to harden and adhere to the previous layer. Then, the plate is raised and the process is repeated until printing is complete.