Today, polyester is much less expensive than other fabrics like cotton, making it an affordable handmade gift option! But can you screen print on polyester? In this article, you will learn how screen printing works. You’ll learn about special tips for printing on polyester fibers. Finally, you’ll discover how water-based inks can affect screen printing. We’ve listed five key tips for polyester screen printing to help you start your project.

Table of Contents

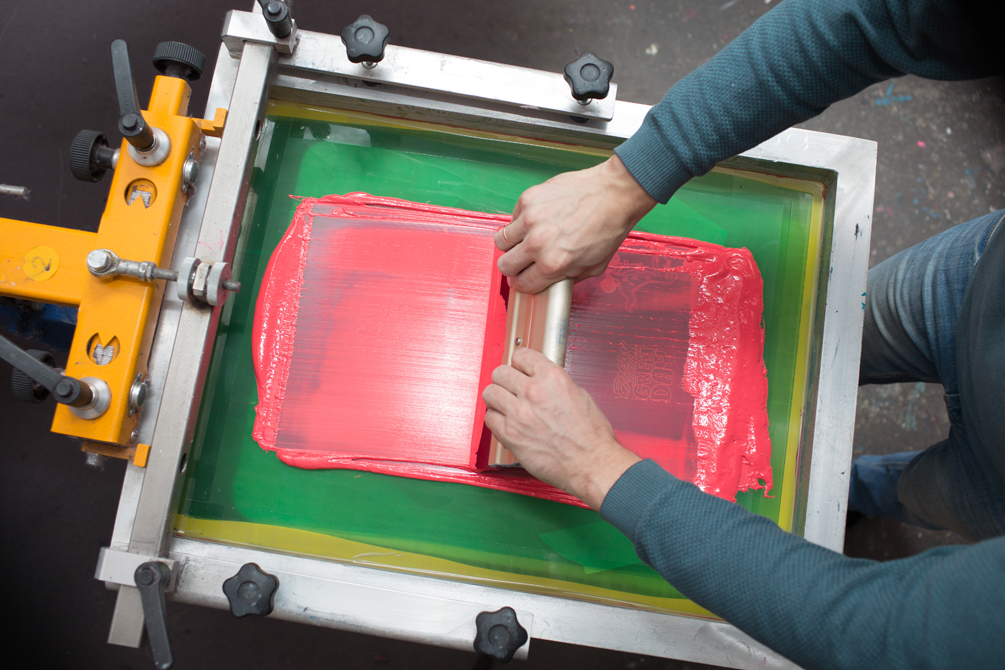

What is Screen Printing?

Screen printing transfers the negative of the image on the screen to the fabric. This printing method usually uses only one or two colors of thick, soft ink. More complex images can use multiple colors on the fabric, one at a time.

Also known as screen printing, this printing method creates a textured raised print on the fabric. This is one of the most popular t-shirt printing methods. (The mesh used in this process used to be made of silk, but today’s cheaper polyester mesh works just as well).

Although screen printing does require some supplies and equipment, it is easier to implement for small batches and DIY projects than other forms of printing. When done correctly, it can also create professional-looking designs.

It takes more time to make a screen print than a digital print, but when you need to print the same design in large quantities, the cost is much lower.

Many commercial printers also use screen printing instead of digital because the print quality is better. Also, screen-printed designs typically last longer than digitally-printed designs. For these reasons, manufacturers or brands that want a solid reputation for quality often opt for screen printing.

Read More: How to Burn Screens for Screen Printing?

Can You Screen Print on Polyester?

You can successfully screen print on polyester, but you’ll have to use different inks and careful temperature measurements to create high-quality designs on synthetic materials. Polyester screen printing presents unique challenges that you won’t encounter if you choose to use 100% cotton. Polyester, on the other hand, costs much less, giving your small business better overhead or a lower gift budget!

Best of all, once you master the process of screen printing on polyester, you will no longer see all the differences between this style of printing and printing on cotton. You’ll soon get used to the necessary precautions to use when printing on polyester!

So, while polyester is a great fabric for screen printing, there are some difficulties. The largest of these is called dye migration.

Dye migration occurs when heat causes some of the color of the fabric itself to bleed into the ink that prints the pattern. Polyester is derived from a fossil fuel polymer that does not work well at high temperatures. Incorrect temperatures can also cause the polyester to shrink, scorch, melt or warp during design set-up.

The good news is that you can prevent these problems by using dark ink in the design or starting with a base underneath the design to prevent any color from oozing out. Of course, carefully measuring the temperature you are using also helps!

You can print images on polyester fibers using a screen printing method called four-color printing. This process breaks down the color of a photo or image into four basic tones, each of which has its own screen during printing. That said, screen printing often (though not always) uses simpler designs that require fewer colors to layer on top of each other.

Can You Remove a Screen Print From Polyester?

When the pattern is not cured, you can scrub the screen print on the polyester with dish soap. You can also find special plastisol removers that can remove silkscreen patterns without damaging polyester fibers. Of course, most designs will also fade over time if you wash your clothes enough!

Read More: How to Clean Screen Printing Screen?

Tips for Screen Printing on Polyester

Choosing the Right Polyester Fiber for Your Screen Printing Project

Different types of polyester blends have their own challenges. Depending on its fiber proportions, polyester mixed with other fibers may prevent the ink from absorbing properly. For example, a 50/50 mix of polyester and cotton may cause dye migration or bleeding during curing, which may change color.

To avoid dye migration, be sure to choose the correct polyester blend for your project and avoid heating the fabric too much during the curing process. A 100% polyester blend will cure the ink well, while less than 65% polyester may cause curing problems.

Need more help choosing the right t-shirt? Read some tips on choosing the perfect T-shirt for silkscreening in our blog post, here!

Choose the right dye for the project

Using polyester requires experimentation with inks before putting a project into mass production. The type of ink you will choose depends on your goals.

Several inks exist. Plastisol inks are synthetic and have bright colors, while water-based inks are more environmentally friendly and softer to the touch. This is because the water-based ink absorbs into the fabric, and the plastisol sits on top of the fabric, creating a stiff feel. For polyester, start with a thin layer of low or no bleed ink to prevent dye migration.

Considering the moisture absorption resistance of polyester fibers, water-based inks require the use of a base. Unlike plastisol inks, water-based inks dry faster, limiting their processability. So if you want to use water-based ink, you can add a deinking agent (or base), but you only have 48 hours to treat the fabric.

Use a base on light or dark fabrics

Depending on the color of polyester you choose, you may need to use a base. This is because various inks work differently on light or dark fabrics.

To help prevent dye migration, use a Stoke white or grey base. A swipe white formula helps stop dye migration. After the sub-base has been laid, any color of plastisol can be applied over it. Conversely, grey undertones are thicker and dry at lower temperatures, which helps slow dye migration. Since it’s thicker, the gray undertone is best for sportswear and not for elegant draping items.

Solve the problem of ink drying during flash curing

A dye may migrate if the fabric is heated too much under flash cure before the final cure. The image is flashed onto the substrate whenever the image needs to be cured. Temperature tape can help you measure fabric temperature on flash cured or conveyor dryers.

If you still can’t get the ink to cure above 300 degrees F, a penetrant synthetic fixer can help cure the ink that would otherwise be difficult to adhere to polyester.

No matter what ink you use to screen print on polyester, you will need to test your ink on the fabric of your choice to avoid color bleed.

Use a slide to keep the artwork flat during heating

Since polyester is a synthetic fiber, a skid plate is required during application and curing. A sheet is a piece of paper or similar material that is placed under the design inside the garment before printing. Polyester fabrics have many air gaps between the threads that allow ink to pass through. This usually happens when printing white ink on dark polyester fabrics.

Can You Print Images on Polyester?

You can screen print images on polyester by separating the colors in the design and then using a separate screen for each color when applying the dye in layers. However, polyester fibers are not suitable for direct printing or DTG printing. If a manufacturer wants to adopt this commercial form of image transfer, a poly blend is usually used.

To transfer a photo or color image onto polyester using screen printing, you need a design program that converts the photo into layers of different colors. You will almost certainly also need to use positive film for each screen.

Honestly, when you’re starting out, you’ll probably find it a lot easier to focus on one or two color designs. The silkscreen looks elegant with nice sharp, clean edges on the raised ink design. This means that even a one-color logo, saying, or team name will look cool!

Read More: How to Fix Cracked Print On Shirt?

Conclusion

Screen printing uses a stencil or negative to apply an image to a mesh screen, transferring a thicker dye to the fabric. Screen printing on polyester works best with special synthetic plastisol dyes. These dyes also require careful temperature conditioning to cure or bond the pattern to the fabric.

Polyester screen printing creates a hooked, slightly raised design with crisp, elegant lines. This design transformation method looks professional and stylish. It also provides a cost-effective option if you need to mass-produce print designs.