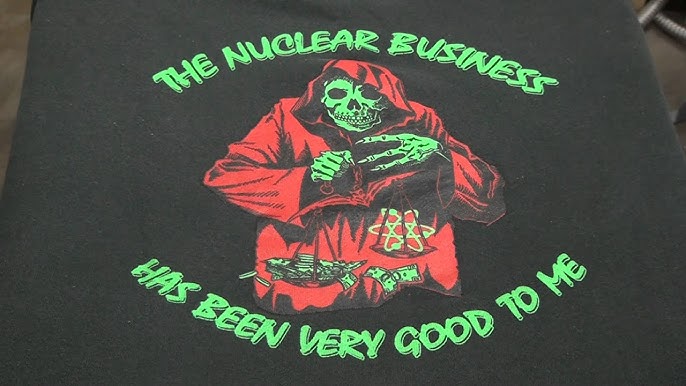

No doubt many of us have experienced some of our favorite screen prints start to fade, crack, peel or fray. Not all use the right method or use good equipment, some think the cheapest inks and materials will do. These practices tend to cause t-shirts to crack, peel, or fade after a few washes, or to wash off your favorite tumbler with your favorite logo after a few uses. So, with the right equipment, process, and right inks, how long will screen printing last?

Table of Contents

What is Screen Printing?

Screen printing, also known as screen printing, is a method of printing art, logos, brand names, and graphics on objects using thick ink. A thin net is pulled tightly around a frame, and the negative of the pattern is printed on the screen. Next, place it directly on a product, such as a shirt. Once everything is set up correctly, the ink rolls onto the screen, and only the area of the printed design allows the ink to slip onto the shirt. After this process is complete, the shirt or item is set aside to dry or cure with a flash cure or exposure unit.

This is a somewhat simplified version of screen printing, as there are other complexities involved, such as which links are used, which chemicals are involved, and the technique, but the above are general aspects of screen printing.

How Screen Printing Works

The screen is coated with a photosensitive material and then exposed to light. After the screen is exposed, the next step is to rinse it off.

Areas of the screen that are exposed to light will be washed away, leaving only the stencil of the design.

Time to install the equipment and start printing! Screen printing ink is pushed through the screen onto the underlying substrate. That’s it, you have a silkscreen print!

Screen printing is a printing technique in which a web is used to transfer ink to a substrate, except in areas where the ink does not penetrate through the stencil.

Move a scraper or scraper across the screen to fill the open mesh with ink. The reverse stroke then briefly touches the screen with the substrate along the line of contact.

This pulls the ink out of the mesh as the screen bounces back after the blade passes. Print one color at a time. Thus, multiple screens can be used to produce multi-color designs.

Read More: How to Burn Screens for Screen Printing?

What Makes Screen Printing Last or Fade?

Factors that affect the longevity of screen prints usually come down to how the screen print is cured. You’ve probably heard some interesting stories from DIYers and small business owners. They’ve just started their screen printing business using kitchen ovens, irons, flash curing, and even a heat gun from the local hardware store. Sadly, neither option properly cures or aids the longevity of screen-printed products and can lead to production difficulties.

The truth is, there aren’t any valuable shortcuts when it comes to therapy. When it comes to making sure your screen print outlasts the product you put on it, it takes careful investment in quality equipment. which is:

- exposure unit

- Belt Oven or Conveyor Dryer

- The infrared flash curing device

The appropriate curing unit also depends on the type of ink used in the screen printing process. The two basic and most commonly used ink types you will find for screen printing are plastisol and water-based inks. Here’s how to successfully cure inks for lasting designs:

Plastisol Ink: The industry standard, known for its opacity and durability. Most plastisols cure at 320°F, some as low as 280°F.

Water-based inks: Known for their soft feel and color. Water-based inks use solvents to carry pigments and need to evaporate to cure properly, so they must have longer dwell times. Cure temperatures range from 90 seconds to several minutes between 300°F and 360°F.

However, once a screen print is properly cured, it does not mean that the product is ready to be sold or shipped to customers. The next step in the screen print is called a “wash test” for professional screen printers, which is the industry standard for assuring print quality and double-checking that the workpiece is properly cured and that the curing unit used is working properly. Washing tests are performed on many items, especially those with special effect, textured, metallic, or gel inks, to ensure that no ink is removed or washed away. Screen-printed products are fully cured and durable.

The next test most professionals will do is called the “stretch test.” Typically, a piece of screen-printed fabric stretches to about half of the material on which the print is placed. Then check for any cracks or flaking. If the image retains its shape when the fabric relaxes, the ink has cured properly.

How Long Does Screen Printing Last?

Screen-printed shirts are a popular clothing option because they are budget-friendly. But how long will a screen-printed shirt last?

With extra care, a screen-printed t-shirt can last for years, or even a lifetime. But there are some things that shorten the life of a print. E.g:

- frequent machine washing

- frequent machine drying

- exposed to the sun

- Improper storage.

Shirts printed with high-quality inks on high-quality materials will last longer than shirts printed with low-quality inks on cheap shirts.

To extend the life of your design and t-shirt, be sure to wash it in cold water and hang it to dry. Avoid ironing the printed area, iron the opposite side of the printed area instead.

Read More: How to Clean Screen Printing Screen?

Does Screen Printing Last Longer?

There are several factors to consider when choosing between screen printing and digital or DTG printing for your project.

An important factor is how long you want the print to last. Generally, screen printing is more durable than DTG printing or thermal transfer printing.

Inks used for screen printing are thicker and more resistant to fading. This makes it ideal for outdoor signs or shirts that are often worn.

This is because the ink in screen printing is pushed onto the fabric through a fine mesh screen. Therefore, this covers the fabric fibers and creates a durable print.

Also, with proper curing, the print is less likely to fade. Digital printing, on the other hand, uses heat to transfer ink to the fabric. Over time, this can cause the ink to crack and peel, especially when the fabric is stretched or bent.

However, DTG printing has come a long way and is almost as durable as silkscreen printing. However, it depends on the type of ink and paper used.

This printing method is less expensive and faster than screen printing, but the ink is more prone to fading and cracking over time.

Washing Your Screen Printed Garment

Assuming your screen-printed garment is properly cared for, it should last as long as any other garment you own.

How often you wear it and what you wear can affect its longevity. With proper care, screen-printed clothing can last a long time.

To make your screen-printed clothes look their best, wash them in cold water with a mild detergent. Avoid using bleach or fabric softeners. Hang or lay flat to dry. If you must iron clothes, iron only on the back. Assuming your screen-printed garment is properly cared for, it should last as long as any other garment you own.

How often you wear it and what you wear can affect its longevity. With proper care, screen-printed clothing can last a long time.

To make your screen-printed clothes look their best, wash them in cold water with a mild detergent. Avoid using bleach or fabric softeners. Hang or lay flat to dry. If you must iron clothes, iron only on the back

Things That Can Shorten the Lifespan of Your Screen Print

Technology has come a long way since the early days of screen printing. There are some very durable inks and fabrics on the market right now. However, there are still things that can shorten the life of a screen print.

The first thing to consider is the fabric to be printed on. Some fabrics, like polyester, are more resistant to fading and abrasion than others. Be very careful when printing on less durable fabrics.

Washing your printed garment inside and out in cold water and hanging it to dry is the best way to care for it. Avoid hot water and dryers.

- wash clothes in hot water

Again, the answer depends on the situation. If you’re talking about screen printing on cotton clothes, it’s probably going to last a long time.

However, if the garment is made of a different material, or if the screen printing is applied directly to the skin, it may not last as long. In general, screen prints should be washed multiple times in hot water without fading or peeling.

If washed in hot water frequently, the print will fade faster than if washed in cold water.

- put clothes in the high heat dryer

It is recommended to dry screen-printed clothes to prolong their life. But we know that not everyone has that kind of time.

If you must put Screenprinted clothing in the dryer, be sure to put it on low heat (or no heat). Remove as soon as it dries. This avoids unnecessary further heat exposure, which will further prevent ink fading.

Conclusion

Screen printing is one of the most durable printing methods. With proper care, your screen-printed garments and detailed designs will last for years.

However, there are a few things that can shorten the life of a screen print. First, frequently washing clothes in hot water or placing them in a high-temperature dryer can speed up the process of fading and crack.

Second, exposing the garment to harsh chemicals or abrasive cleaners will also start to degrade the design.

Finally, if you don’t store your clothes properly, the prints can warp and crack.